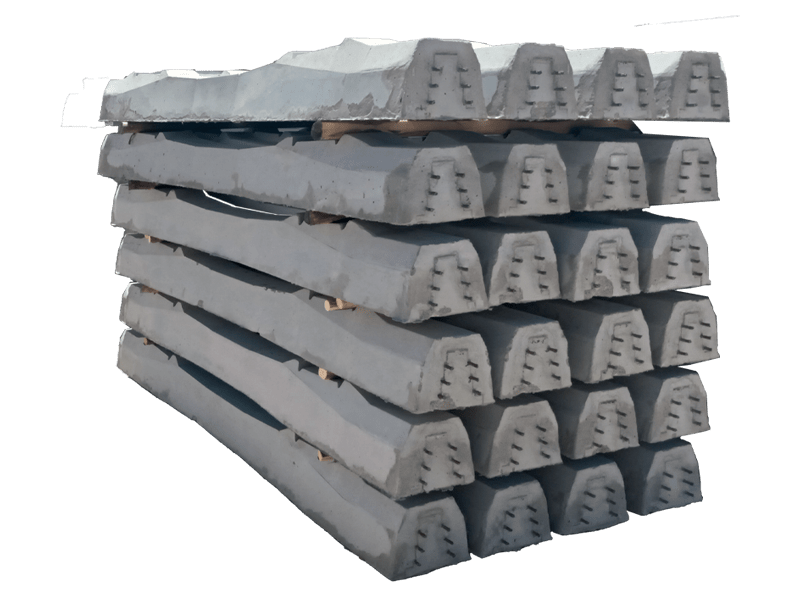

Concrete sleeper is a basic element in the railway lines, which is used to maintain the rail and distribute the load on the base layer. Conrete sleepers are designed to transfer load from the rail to other parts of the structure and are placed along the railway lines. Concrete sleepers are suitable for use in railway lines due to their high strength and hardness, long life and reduction of vibration and noise during train passage.

There are different concrete sleepers according to their shape and dimensions. Different types of concrete sleepers can be used according to the needs of railway lines and local conditions.

The use of concrete sleeper in railway lines dates back to the 19th century in England. In the beginning, high-height wooden sleepers were used as the main element in the construction of railway lines. But with the emergence of reinforced concrete technology, wooden sleepers gradually gave way to reinforced concrete sleepers. In the following years, due to the mechanical properties and higher strength of reinforced concrete sleepers than wooden sleepers, their use in the construction of railway lines was expanded. Also, the advancement of reinforced concrete technology brought improvement in the quality and performance of concrete and reinforced concrete sleepers. Currently, reinforced concrete sleepers are used as the main element in the construction of railway lines around the world, and due to their advantages over wooden sleepers, their use is expected in the future.

Concrete sleepers in railway lines have many advantages. Firstly, with high strength, it has the ability to bear heavy loads and shows significant resistance to pressure and lateral forces. Also, due to its three-dimensional structure, it has high stability against lateral forces. The use of pre-stressed strands inside the concrete sleepers increase its resistance and makes its useful life practically longer. Also, due to its long-term stability, concrete sleepers remain in the railway lines for years without needing to be replaced. Finally, concrete sleepers recyclable and can be recycled and reused after replacement.

The production method of prestressed concrete sleepers is continuous and non-continuous. In the non-continuous method, the mold is first prepared and the prestressing strands are installed inside the mold. Then the initial tension of the wires is applied and then the final tension is done. After that, concrete casting and vibration is done, and after the concrete is cured, sleepers removed from the mold. Then the seat is installed on the sleepers and finally, sleepers have their environmental protection in the holes on both sides.

But in the continuous method, sleeper forms are placed along the joint and the strand is installed along with other accessories. Then the tension of the strands is applied and concrete is poured and concrete is vibrated. Then, by covering the sleepers with tarpaulin fabric, the concrete curing is done. After the end of the concrete curing process, the sleepers are cut and separated. Finally, the seat is installed on sleepers and the produced sleepers are stored in the depot and transported to the construction site of the railway line.

kamran –

thank you