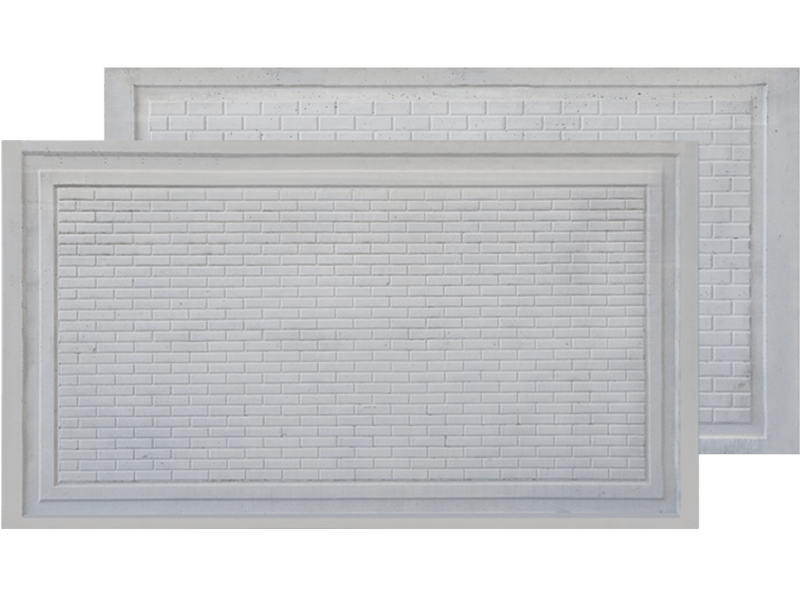

Precast concrete wall

Due to the progress of the construction industry and mass production, the importance of increasing the execution speed and the use of precast products have become more common. One of these products is the precast concrete wall. In the construction of precast concrete wall, raw materials such as cement, aggregate, water, additives and rebar are used. For the production of precast concrete wall, cement and aggregate must be used that are in accordance with the national standards of Iran. When pouring concrete in the form of a precast wall, quality lubricants should be used to achieve proper and smooth adhesion and easy polishing. The water used in the construction of precast concrete walls should be free of organic, acidic and alkaline substances and should be smooth and clean. Also, using standard A3 grade rebars with high tensile strength is more suitable for building precast concrete walls.

Precast concrete wall raw materials

Concrete and reinforcement are used in the construction of precast concrete walls. The price of these walls changes due to the fluctuations in the price of materials. There are four types of precast concrete walls: 1- one-sided wall including simple walls and fences, 2- double-sided wall and 3- self-standing wall. The price of each type of precast concrete walls is different for different reasons and according to the thickness, type of rebar and grade of concrete.

Price of precast concrete wall

The price of each square meter of precast concrete wall varies depending on the thickness of the wall. With the increase in thickness, the price of precast concrete wall will increase. The type of precast wall based on its simplicity or design has a significant role in its price. In general, the one-sided wall is cheaper, and the price per square meter of the double-sided concrete wall (both sides) is more expensive than the other two types.

The price of cheap precast concrete walls include simple walls, with a small thickness, with smaller size bars and with a lower grade of concrete. When buying a precast concrete wall, you should be careful that the wall has the required quality. Otherwise, buying cheap will not only lead to profit and will bring additional costs over time. In other words, the cheap price of the precast concrete wall should not be the main criterion in the choice. Buying precast concrete walls should be done from reliable sellers. You can see the exact price and detailed specifications of the concrete wall piece on Hamyar Beton Shirkoh’s website. When buying a precast concrete wall, attention should be paid to the size of the area, the desired height of the wall and the place of execution. To determine the required square footage to buy a precast concrete wall, you need to calculate the area. Precast walls are generally produced in heights and lengths of 2 to 4 meters and are selected and purchased according to its use. Also, the higher built-up wall can generally be made and produced in meter lengths and should be considered in its purchase.

Precast concrete wall with two faces is a type of wall that is produced from precast concrete and has two faces. The use of this type of concrete wall significantly increases the speed of implementation and construction. In addition to the high speed of installation, this wall is removable and can be easily moved to another location. Also, the strength and longevity of these walls are very high and they have good resistance in different weather conditions. Various designs can be made and produced from this wall, and logos of various organizations can be installed on it.

Fencing using precast concrete wall in extreme geographical and climatic conditions is possible. Due to the construction of these walls, the need for their maintenance is less and it is also possible to implement them in different weather conditions. While the implementation of traditional walls in adverse climatic conditions has many problems. Another advantage of this concrete wall is the ability to install it on sloping surfaces.

abbasi –

Excellent product